This guide covers the fundamentals of pouch sizing, including how to measure dimensions correctly, account for product volume, and—critically—how to adjust pouch specifications when transitioning from manual to automated packaging operations.

How to Size a Stand Up Pouch

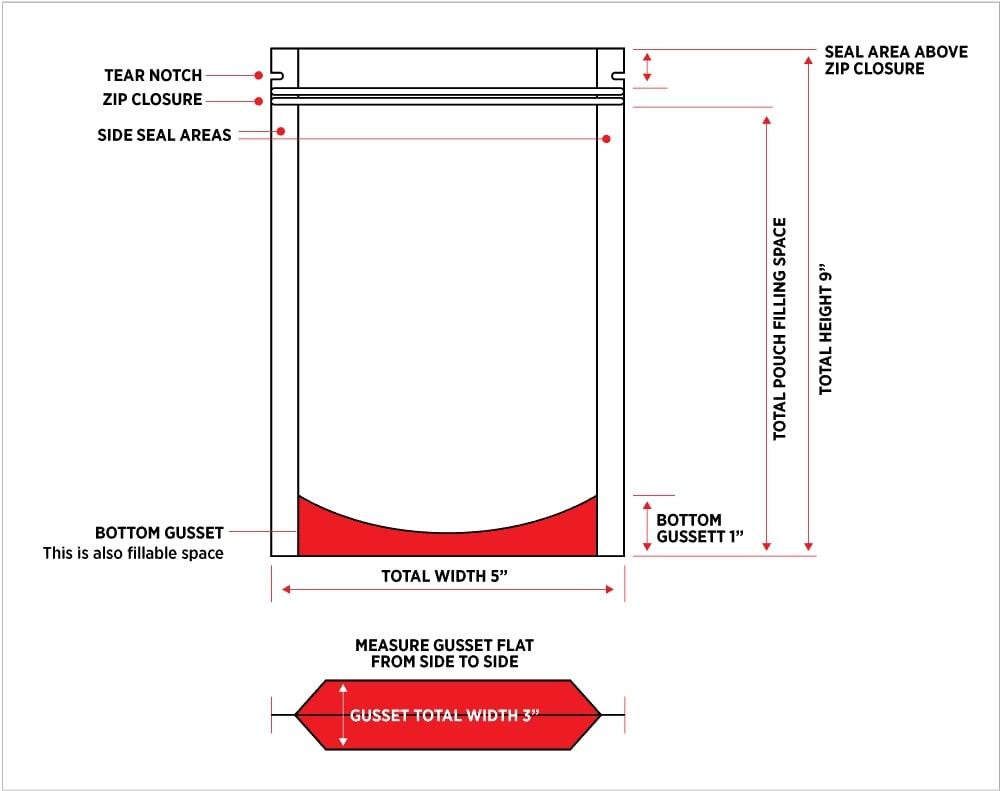

Pouch dimensions are typically listed in the following order: width, height, and gusset. If you see a third dimension, the pouch has a bottom or side gusset that allows it to stand upright on shelves.

When measuring a gusseted bag, open the pouch and measure from front to back along the bottom. Note that some manufacturers list half the measured length as the gusset size, while others state the entire gusset length.

All pouch measurements are based on outside dimensions—not the interior fillable space. This distinction matters more than most people realize.

The Fillable Space Problem

A 6 x 8-inch pouch won't fit a 5 x 6-inch product as cleanly as the numbers suggest. Here's why:

- Pouch features reduce interior space. Zip closures, seal dimensions, tear notches, and hang holes are all included in the overall dimensions. The fillable space is the area below the zipper or heat-seal line and extends to the bottom of the pouch.

- Testing with your actual product is non-negotiable. Paper calculations get you in the ballpark. Physical testing gets you the answer.

Understanding Product Volume

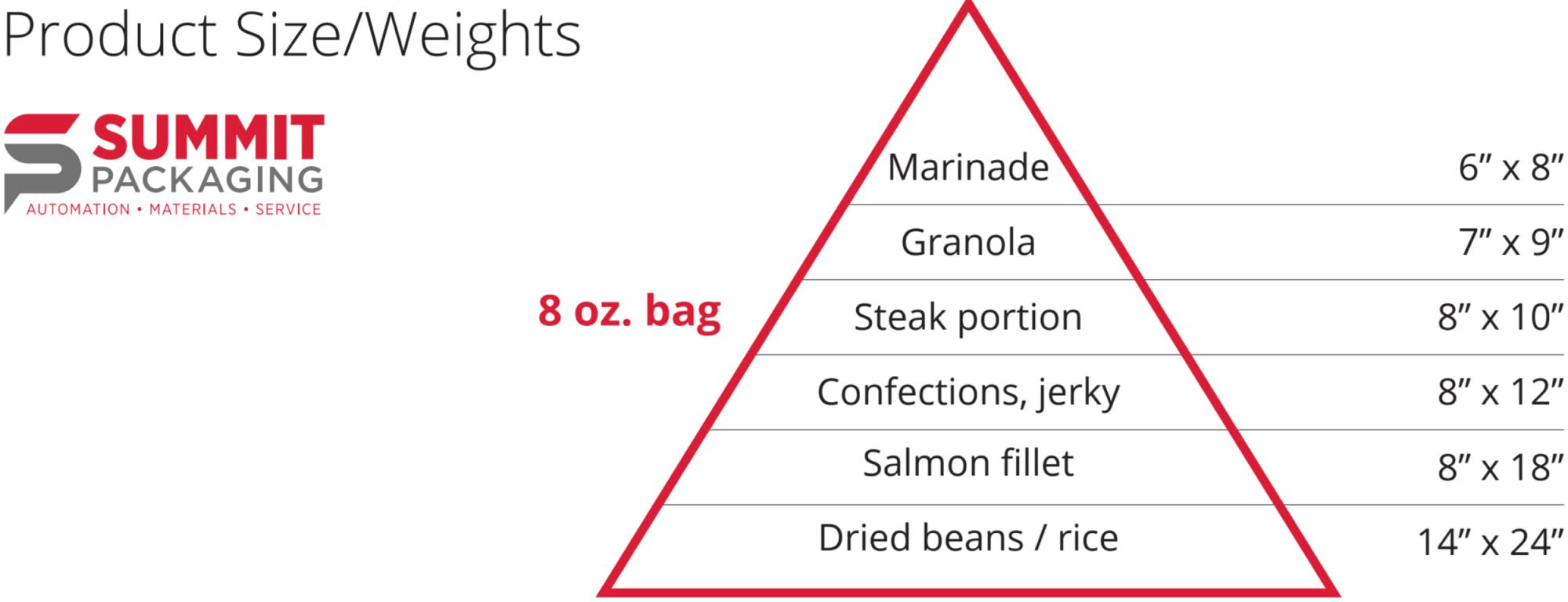

Eight ounces of salmon takes up far less space than eight ounces of granola. Density determines how much pouch you actually need.

For bulky, lightweight products (trail mix, puffed snacks, leafy herbs), you may need a pouch a full size larger than the weight alone would suggest. Dense products like nuts, dried fruit, or meat allow for more compact packaging.

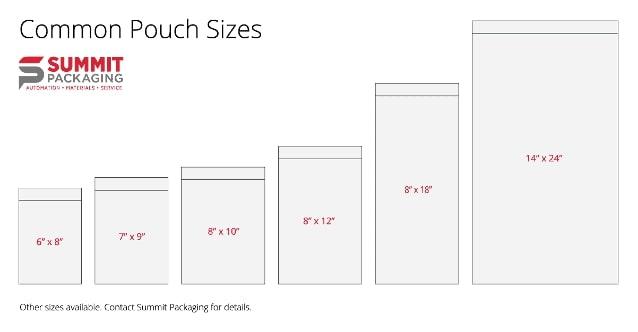

Common stock stand-up pouch sizes range from 6x8 inches to 14x24 inches. At Summit Packaging, we offer standard sizes alongside custom options for products that don't fit neatly into off-the-shelf solutions.

Volume Reference by Product Type

| Product Category | Density | Sizing Consideration |

|---|---|---|

| Granola, trail mix, puffed snacks | Low (bulky) | Size up for volume, not weight |

| Nuts, dried fruit, jerky | Medium | Standard sizing typically works |

| Coffee, protein powder | Medium-High | Account for settling and seal area |

| Fresh meat, fish | High (dense) | Focus on barrier properties over size |

| Liquids, sauces | High | Consider gusset for stability |

How Your Filling Method Affects Pouch Size

The equipment you use to fill pouches directly impacts the pouch dimensions you need. This is where many operations encounter unexpected complications—especially when scaling from hand-filling to automated systems.

Manual Filling Requirements

Hand-filling offers flexibility. Operators control the flow of product into the pouch, can adjust positioning in real time, and ensure product settles comfortably before sealing. The pouch opening doesn't need to accommodate any fixed equipment—just the product itself.

When sealing by hand, operators can squeeze both sides of the film together or settle the product toward the bottom to create a clear seal area. This human adaptability allows manual operations to often accommodate tighter pouch dimensions.

Automated Filling Requirements

Automated systems introduce mechanical constraints that manual operations don't face. Understanding these constraints before selecting equipment—or before scaling up—prevents costly pouch redesigns mid-project.

Funnel Clearance and Product Flow

Automated weigh-fill systems use funnels to drop product quickly and accurately into the pouch. The pouch opening must be wide enough to accommodate this funnel with sufficient clearance to:

- Prevent product spillage during the fill cycle

- Allow product to flow naturally without bridging or clogging

- Maintain target fill speeds (packages per minute)

For these reasons, automated systems often require additional pouch width and/or length compared to the same product filled by hand.

Sealing Bar Requirements

Automated sealers have specific sealing-bar widths and require a consistent, flat material surface to ensure reliable seals. This mechanical requirement necessitates a larger, more uniform border around the sealing area than an operator might use when hand-sealing.

Mechanical Grippers and Transport

Bagging machines use mechanical grippers to transport pouches through opening, filling, and sealing stations. These grippers may require additional material to hold the pouch reliably throughout the process. If your existing hand-filled pouch dimensions are too small, the pouch may be incompatible with the machine's handling components.

Sizing Pouches for Automation: A Real-World Example

When transitioning from manual to automated packaging, pouch dimensions may need to be adjusted. Here's how we approach this with customers making that transition.

The Scenario

A producer packaging hazelnuts in three sizes (8oz, 16oz, and 32oz) was moving from a manual process (weighing by hand, filling into pouches, and labeling each item) to an automated system that would weigh, fill, seal, and label in a single integrated process.

The goal: achieve 20-30 packages per minute while reducing labor costs.

The Challenge

The customer's existing pouches were sized for manual filling. The question: would those dimensions work with automated equipment, or would adjustments be necessary?

Rather than assuming compatibility, we recommended testing the product on the actual equipment to determine whether sizing changes were needed, and, if so, by how much.

The Testing Process

We took the target net weights for each pouch size and sent that amount of hazelnuts to the equipment manufacturer's facility. Their engineers ran the product through the system and determined the optimal length, width, and bottom-gusset dimensions needed to:

- Accommodate the filling funnels and product drop

- Provide adequate seal area for consistent closures

- Meet the target packaging speed of 20-30 packages per minute

- Work reliably with the machine's mechanical grippers

The Outcome

Testing revealed that an additional 1-1.5 inches in width and length would be sufficient to meet the customer's speed and reliability goals across all three pouch sizes.

The customer acknowledged that this modest size adjustment was a worthwhile trade-off for the increased packaging speeds and reduced labor costs that automation would deliver.

When to Test Pouch Compatibility with Equipment

If you're considering automated packaging equipment, evaluate pouch sizing as part of the equipment selection process—not after. Key questions to address:

- What are the funnel dimensions? Ensure your pouch opening provides adequate clearance.

- What seal bar width does the equipment use? Verify your pouch provides sufficient flat material above the fill line.

- What are the gripper specifications? Confirm your pouch dimensions work with the transport mechanism.

- What's the target speed? Higher speeds may require additional dimensional allowances for reliable operation.

- Can the equipment manufacturer test with your actual product? If possible, send samples for evaluation before finalizing pouch specifications.

Stock Stand Up Pouches

Standard pouch sizes meet many application needs without requiring custom production. Common stock sizes include:

- 6 x 8 inches

- 7 x 9 inches

- 8 x 10 inches

- 8 x 12 inches

- 14 x 24 inches

Each product is different, and exact specifications matter for both product protection and operational efficiency. Our packaging specialists can help match your product to the right standard size—or determine when custom sizing makes more sense.

Custom Stand Up Pouches

When standard sizes don't fit your product—or when you're optimizing for specific equipment—custom stand up pouches can be sized to virtually any dimension you need.

Custom sizing is particularly valuable when:

- Your product has unusual dimensions or density characteristics

- You're integrating with specific automated equipment

- You need precise control over shelf presentation

- Standard sizes create excessive waste or underfilling

Our packaging team works with customers daily to develop accurate custom sizing. We've solved these problems for products ranging from candy and beef jerky to hardware and specialty coffee.

Why There's No Universal Pouch Size Calculator

A simple "enter your product weight, get your pouch size" calculator would be convenient—but it would also be wrong more often than it's right.

Every product and application combination is unique. Product density, flow characteristics, packaging equipment, seal requirements, and shelf presentation all influence the optimal pouch size. This variety requires testing and iteration to find the right fit.

The sizing strategies in this guide give you a solid starting point. From there:

- Test at home. Find a pouch on your shelf holding a similar product. Empty it and fill it with your product to gauge the size you need.

- Visit a grocery store. Purchase the type of pouch relevant to your product and test-fill with your own material.

- Request samples. Our team provides packaging samples and guidance on sizing—including recommendations for equipment compatibility.

What’s next?

Whether you're selecting pouches for hand-filling or planning a transition to automated packaging, proper sizing starts with understanding your specific requirements.

Contact a Summit Packaging representative for:

- Packaging samples matched to your product

- Guidance on sizing for manual or automated operations

- Material structure recommendations for your filling equipment and process

- Custom sizing development for unique applications

We specialize in stand up pouches and work with customers at every stage—from initial product development through high-volume automated production.