- The Solution to Labor Shortage

- Understanding Your Needs

- Data-Driven Decisions

- Presenting Solutions & Transparency

- Seamless Implementation & Beyond

- Our Proven Methodology

- Cutting-Edge Technology

- Feasibility Project Steps

- Why Choose Summit Packaging?

- Goals & Deliverables

- Automation Case Studies

- Maintenance & Service

- Conclusion

At Summit, we believe introducing automation doesn't have to be a complex or daunting process. We offer a comprehensive approach that takes you from initial problem identification to a fully implemented and optimized solution, all backed by our extensive experience and industry expertise.

Article Main Points

- Summit Packaging leverages automation to address labor shortages and enhance production efficiency.

- Customized automation solutions are tailored to meet company-specific needs and operational goals.

- Data-driven decision-making processes help refine operations and identify areas for improvement.

- Transparent implementation and continuous support ensure smooth adaptation and long-term production gains.

- Integration of Lean principles and the Theory of Constraints optimizes workflows and eliminates bottlenecks.

The Solution to Labor Shortage

Summit Packaging addresses the labor shortage by leveraging automation for heightened production efficiency and reduced workforce dependency. Automation serves as a solution to immediate labor gaps and supports long-term workforce management. By assigning repetitive and strenuous tasks to machines, human workers can by reassigned to pivotal roles, enhancing skill preservation and job satisfaction.

This tactical redistribution of tasks leads to substantial financial benefits, curtailing the need for a vast number of employees, and lessening the economic effects of high staff turnover and hiring difficulties. Furthermore, the incorporation of technology in manufacturing processes enables continuous production refinement. Automated machinery ensures streamlined operations, minimizes mistakes, and upholds consistent product quality, vital for satisfying both present and prospective production requirements.

Summit Packaging's strategy not only demonstrates a dedication to overcoming labor challenges with pioneering methods but also highlights the necessity to adapt swiftly and perceptively to industrial shifts. By concentrating on immediate and strategic requirements, Summit Packaging equips manufacturers to navigate the changing market landscape with assurance and effectiveness.

Understanding Your Needs

Summit Packaging tailors automation tools to your company's specific requirements by initially assessing your operational needs thoroughly. In collaboration with your team, this examination, focusing on your current assembly lines, array of products, and expansion aspirations, identifies essential areas for potential enhancement through automation.

Our strategy prioritizes refining processes and boosting efficiency. We pinpoint and address bottlenecks and inefficiencies, crafting tailored interventions aimed at simplifying workflows and increasing output. This approach not only meets immediate needs but also paves the way for ongoing advancements, adapting your production methods to meet future demands and opportunities.

Data-Driven Decisions

Summit Packaging employs data as the cornerstone of strategic choices. We utilize various tools and techniques to gather and analyze data about your current production process. This data, combined with our industry knowledge, allows us to develop a customized automation plan that aligns perfectly with your unique requirements.

This scrutiny supports decision-making. Detailed examination of your current workflows pinpoints efficiency enhancements and cost reductions. This boosts your manufacturing capabilities.

Data's role at Summit Packaging transcends simple gathering and analysis. It shapes every decision, fostering ongoing advancement. This strategic use of data aids your enterprise in achieving notable manufacturing improvements and maintaining competitiveness in a tough marketplace. This approach not only optimizes operations but also ensures that investments in mechanization deliver substantial, beneficial outcomes.

Presenting Solutions & Transparency

Once we have a clear understanding of your needs, we present you with a range of potential automation solutions to enhance your production efficiency. These systems, customized to your unique manufacturing needs, ensure seamless operations. By involving clients at every step, we maintain a transparent process and empower you to choose solutions that best align with your operational goals and financial limits.

Key aspects of our solution presentation include:

- Efficiency Benefits: Each system is designed to remove operational barriers and increase throughput.

- Customized Systems: We adapt our automation tools specifically for your manufacturing requirements.

- Cost Savings: We highlight the financial benefits of each system by comparing long-term savings to initial investments.

- Transparent Process: We ensure you understand the implications and benefits of each system through clear explanations and open discussions.

- Improved Product Quality: Our automation systems not only accelerate production but also consistently boost product quality, minimizing waste and rework.

Our goal is to equip you with the knowledge and tools necessary for informed decision-making, fostering sustainable growth and operational excellence.

Seamless Implementation & Beyond

Our commitment goes beyond simply recommending equipment – Summit Packaging ensures a seamless transition to automated systems. We supervise each stage of the project lifecycle, from conducting detailed feasibility assessments to selecting precise machinery, overseeing installation, providing training, and offering continuous support. This comprehensive method not only secures successful automation implementation but also boosts workforce efficiency on production lines.

By prioritizing machine dependability and effective project oversight, Summit Packaging reduces disturbances, achieving rapid and efficient production enhancement goals. Continuous support and training are fundamental to our approach, facilitating a smooth adaptation for staff and maintaining high operational standards after the system is in place.

At Summit Packaging, we commit to thorough planning and execution, ensuring that automation solutions are not merely installed but are effectively integrated and sustained, delivering lasting advantages and aiding clients in reaching their long-range productivity and efficiency objectives.

Our Proven Methodology

At Summit Packaging, we leverage a combination of best practices to ensure the success of your automation project. We employ a trusted strategy, integrating Lean Methodology and the Theory of Constraints. This strategy, crafted for maximizing process enhancement and driving efficiency improvements, focuses on bottleneck elimination and workflow enhancement. The strategy ensures that each automation solution is effective, scalable, and aligned with the company's strategic goals.

Key elements of the strategy include:

- Lean Methodology & Theory of Constraints: We utilize Lean principles and the Theory of Constraints to identify and eliminate bottlenecks in your production line. This ensures that your automation efforts are targeted and result in the most significant gains in efficiency.

- Phased Implementation Plan: We understand that not every company has the budget or resources for a complete automation overhaul. That's why we offer a phased implementation plan. This allows you to prioritize "low-hanging fruit" – the areas where automation can yield the biggest initial benefits – and then scale up over time as your needs and budget evolve.

Through this systematic strategy, Summit Packaging not only addresses immediate manufacturing issues but also prepares for enduring operational achievement, aiding clients in managing the complexities of contemporary manufacturing settings.

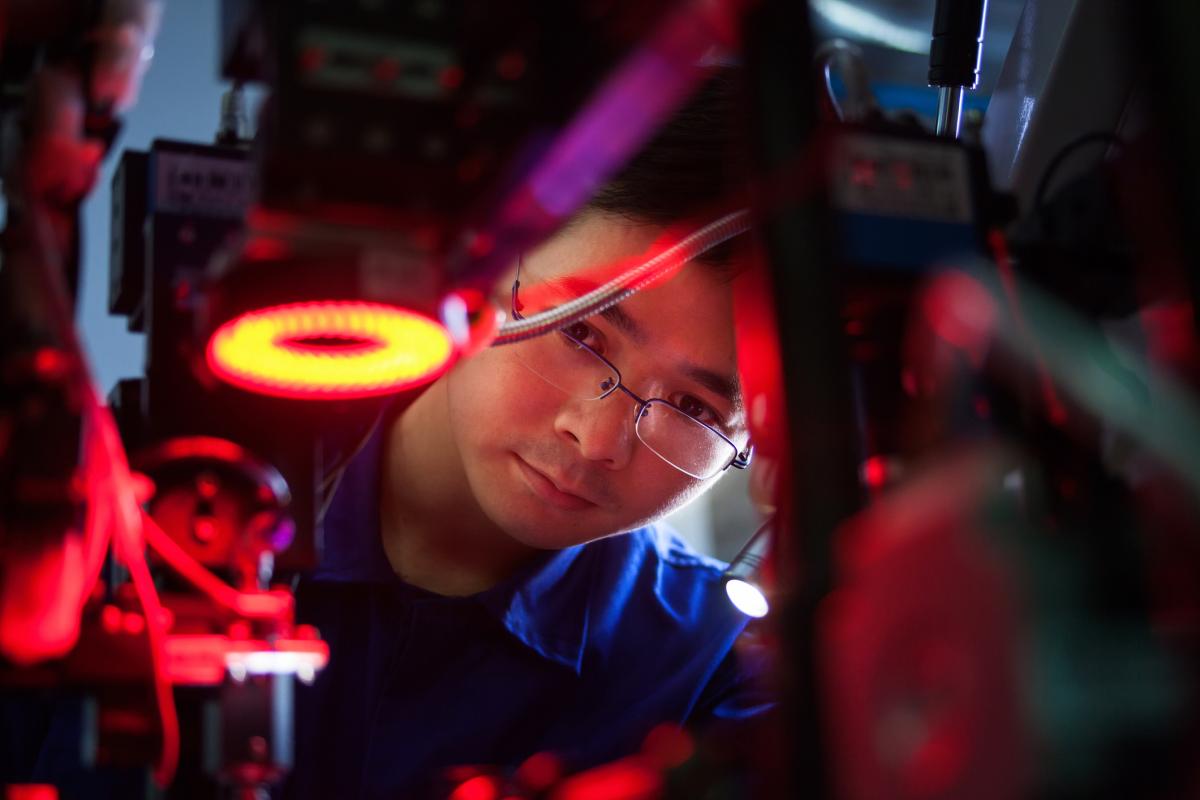

Cutting-Edge Technology

We stay at the forefront of automation advancements, incorporating cutting-edge technologies like robotics, artificial intelligence (AI), and machine learning into our solutions. This allows us to design smarter, more adaptable systems that can learn and adjust to your specific production needs over time. Our technology integration transforms conventional assembly lines into nimble and scalable operations.

Through advanced devices and computation intelligence, our frameworks offer significant inventive advantages. These technologies enable swift adjustments to fluctuating production needs, making our systems adaptable and responsive. Learning models analyze operational data continually, enhancing performance and forecasting maintenance, thus minimizing idle times and boosting productivity.

Feasibility Project Steps

Summit Packaging begins each project with a systematic approach. Identifying each customer's unique manufacturing challenges and workforce solutions is essential.

Here's a closer look at our step-by-step process for feasibility projects:

- Kick-off Meeting: We begin with a collaborative meeting to understand your goals, challenges, and production environment.

- Baseline Measurements: We gather baseline data on your current production process, including cycle times, throughput, and labor requirements.

- Process Flow Mapping: We create a detailed map of your current production line, identifying each step and potential areas for improvement.

- Bottleneck Identification: Through data analysis and process mapping, we pinpoint bottlenecks that are hindering your efficiency.

- Implementation Strategies: Based on our findings, we develop a range of potential automation solutions tailored to address your specific bottlenecks and goals.

Each phase is carefully planned and executed, to ensure that technological interventions are both feasible and beneficial. This leads to a more efficient, smoother manufacturing operation.

Why Choose Summit Packaging?

Selecting Summit Packaging as your automation ally presents clear benefits. We differentiate ourselves through several key factors:

- Experience & Expertise: We have a proven track record of helping companies across various industries successfully implement automation solutions.

- Market Knowledge: We stay up-to-date on the latest automation trends and technologies, ensuring you have access to the most advanced solutions available.

- End-to-End Project Implementation: We handle everything from initial assessments to ongoing support after the installation and training, providing a seamless experience for our clients.

- Competitive Pricing & Project Timelines: We offer competitive pricing and deliver projects on time and within budget.

Summit's deep understanding of diverse industrial sectors ensures the development of both effective and enduring strategies.

Moreover, Summit champions eco-friendly practices in automation, aiding your enterprise in achieving both production targets and environmental commitments. Opting for Summit Packaging means selecting a committed partner invested in your enduring success.

Goals & Deliverables

Our primary goal is to help you achieve your production objectives, whether it's increased output, improved efficiency, reduced labor costs, or a combination of these goals. Here are some key deliverables you can expect when partnering with Summit Packaging:

- Process Map Assessments: We provide a detailed analysis of your current production line, identifying areas for improvement.

- Feasibility Studies: We conduct in-depth feasibility studies to ensure the recommended automation solutions align with your budget and long-term goals.

- Implementation Plans: We create comprehensive implementation plans that outline the entire project lifecycle, including timelines, milestones, and resource allocation.

Automation Case Studies

Automation significantly boosts production metrics and operational efficiency. At Summit Packaging, our strategic interventions in automation have proven effective across various sectors. We're proud of the success stories we've helped create. Here are a few examples of how we've partnered with companies to achieve their automation goals:

- Increased Production Volume by 30%: We helped a food and beverage manufacturer implement a robotic palletizing system, resulting in a significant increase in production volume within a single quarter.

- Improved Efficiency by 25%: We collaborated with a pharmaceutical company to automate their packaging line, leading to a 25% improvement in overall production efficiency.

- Reduced Labor Costs by 15%: We designed and implemented a customized automation solution for a manufacturing client, resulting in a 15% reduction in labor costs.

These are just a few examples of our dedication to delivering high-value automation setups that tackle intricate production and workforce issues, achieving measurable improvements in efficiency, significant cost reductions, and impactful industry changes.

Maintenance & Service

To ensure the performance and lifespan of systems, we offer comprehensive maintenance and service plans. These plans are essential for maintaining optimal functionality in addressing workforce shortages. This includes:

- Local Field Service Technicians: We have a network of local technicians strategically located throughout the region to provide prompt on-site support.

- Preventative Maintenance Programs: We offer preventative maintenance plans to identify and address potential problems before they cause downtime.

Summit Packaging not only resolves immediate system concerns, but also focuses on sustained operational excellence.

Conclusion

In today's competitive landscape, automation is no longer a luxury, it's a necessity. Embracing automation is crucial for modern manufacturing success. At Summit Packaging, we partner with you to develop and implement customized automation solutions that address your specific needs and unlock significant production gains.

Summit Packaging crafts tailored solutions for each production facility, tackling specific operational challenges. We leverage our extensive experience, industry knowledge, and commitment to excellence to ensure your success.

Contact us today to schedule a free consultation and learn how Summit Packaging can help you bridge the labor gap and achieve your automation goals!